Mobile Platforms Adaption

Diversified Application Scenarios

Compact & Lightweight

Dexterous & Flexible

Sufficient Payload

Sufficient Accuracy

Support Joint Force Control

With Collision Protection

Open Programming Interface and Extended Interface

The manipulator control program and control interface will be successively opened, and different actuators can be quickly replaced at the end of the manipulator.

Application

Various mobile robots’ onboard manipulator, e-commerce logistics, new consumption, daily life, etc.

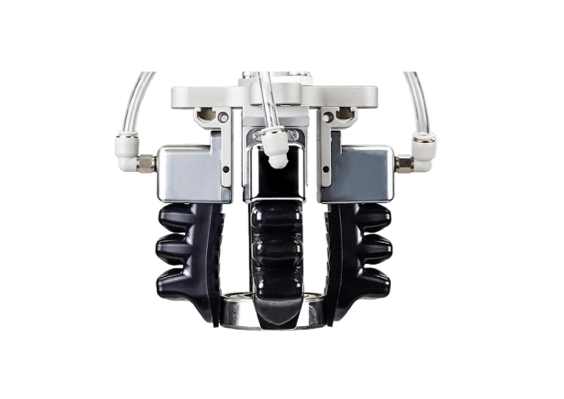

FUNCTION

PARAMETER

Backlash

~6 arcmin

Communication Method

RS 485

Maximum Torque

33N·m

Encoder Resolution

15bit

Weight

405g

Force Control Accuracy

~0.2N·m

Size

Φ65*52mm

Control Frequency

1KHz

Reducer

Harmonic Reducer

Bearing

Industrial grade cross roller

Reduction Ratio

60+

Motor Sensing Feedback

Torque, Angle, Angular Velocity

Voltage

24V(Recommend)

Motor Control Command

Torque, Angle, Angular Velocity, Stiffness, Damping

and other mobile robots,

to complete complex tasks and explore various

application scenarios.

Parameter

Model

Z1 AIR

Z1 PRO

DOF

6 Axis

6 Axis

Weight

4.3kg

4.5kg

Payload

2kg

≥3kg

Reach

740mm

740mm

Repeatability

~0.1mm

~0.1mm

Power Supply

Voltage 24V Current > 20A

Voltage 24V Current > 20A

Interface

Ethernet

Ethernet

User Operating System

Ubuntu

Ubuntu

Power

MAX 500w

MAX 500w

Force Feedback and Collision Detection

Provide

Provide

Control Interface

Position + Force Control

Position + Force Control

Joint

Range

Max Speed

Joint Parameters

J1

±150°

180°/s

J2

0-180°

180°/s

J3

-165°-0

180°/s

J4

±80°

180°/s

J5

±85°

180°/s

J6

±160°

180°/s

[1]

It depends on the actual test according to the use requirements (the test standards of manipulator vary greatly, and the accuracy varies greatly under different test conditions).

[2]

Since the reduction ratio used by each joint is relatively low, the position control stiffness of the whole machine is low. If the control mode is not optimized, there will be large position control error and shaking when the manipulator moves.

This product is a civilian robot. We kindly request that all users refrain from making any dangerous modifications or using the robot in a hazardous manner.

Please visit Unitree Robotics Website for more related terms and policies, and comply with local laws and regulations.